Additive manufacturing techniques so far have found application predominantly in industrial production processes due to high costs of the materials used and the specialized technology associated with the technique. Recently, there is growing interest in the development of automated fabrication techniques for concrete structures in the construction industry. Most of these novel additive manufacturing processes are based on extrusion techniques, see Fig. 1 left. Due to the time dependent rheological properties of fresh concrete, 3D-concrete-printing processes require a variable and dynamically adjusted control of the manufacturing process. Therefore, properties of 3D-printed concrete structures are much more dependent on the fabrication process as compared to conventionally casted structures.

To this end, numerical models can assist to understand the complex interactions between the printing process and the evolution of structural parameters throughout the manufacturing process. Hence, a numerical model based on the Particle Finite Element Method (PFEM) is developed at the institute for structural mechanics for the analysis of extrusion processes in 3D-concrete-printing.

The printed material is in a flowable and extrudable state and is thus modelled with a non-Newtonian Bingham fluid. In 3D analyses interactions between structural response, process parameters and material properties are discussed.

3D-Concrete-Printing: 3D Analysis – Three-Layer Test

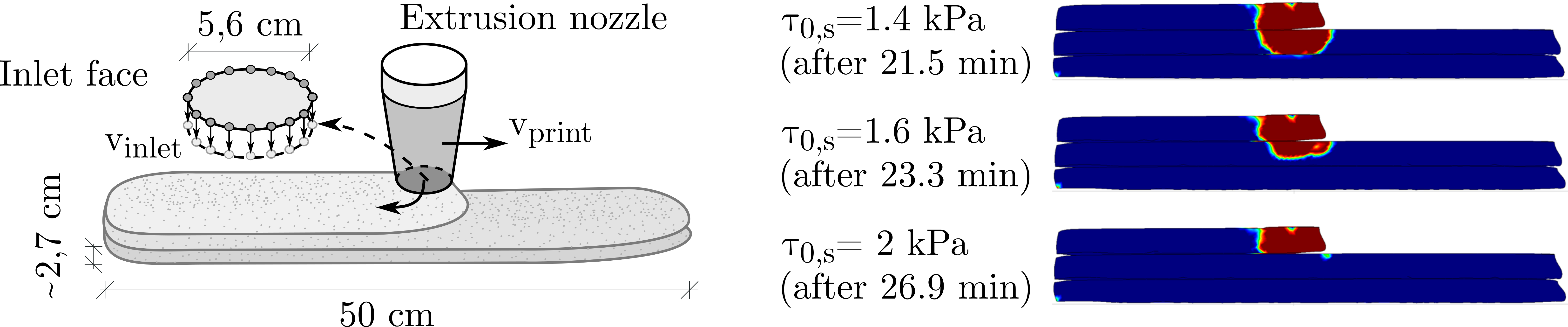

The structural response and shape stability properties of the material during the 3D-concrete-printing process are assessed in this analysis. Therefore, a numerical study of three printed layers is performed, see Fig. 1 left. In Fig. 1 right the time instance, when the third layer is printed is given along with the yielded (red) and unyielded (blue) regions. The results are given for three different static yield stresses (or waiting times between each layer). As can be seen, for the lowest static yield stress (or youngest material age) lower layers are plastically deformed from the pressure of the inlet flow and unwanted deformations of lower layers occur. If the waiting time is long enough, lower layers gained enough strength to bear the impact load from the inlet flow (see Fig. 1 right).

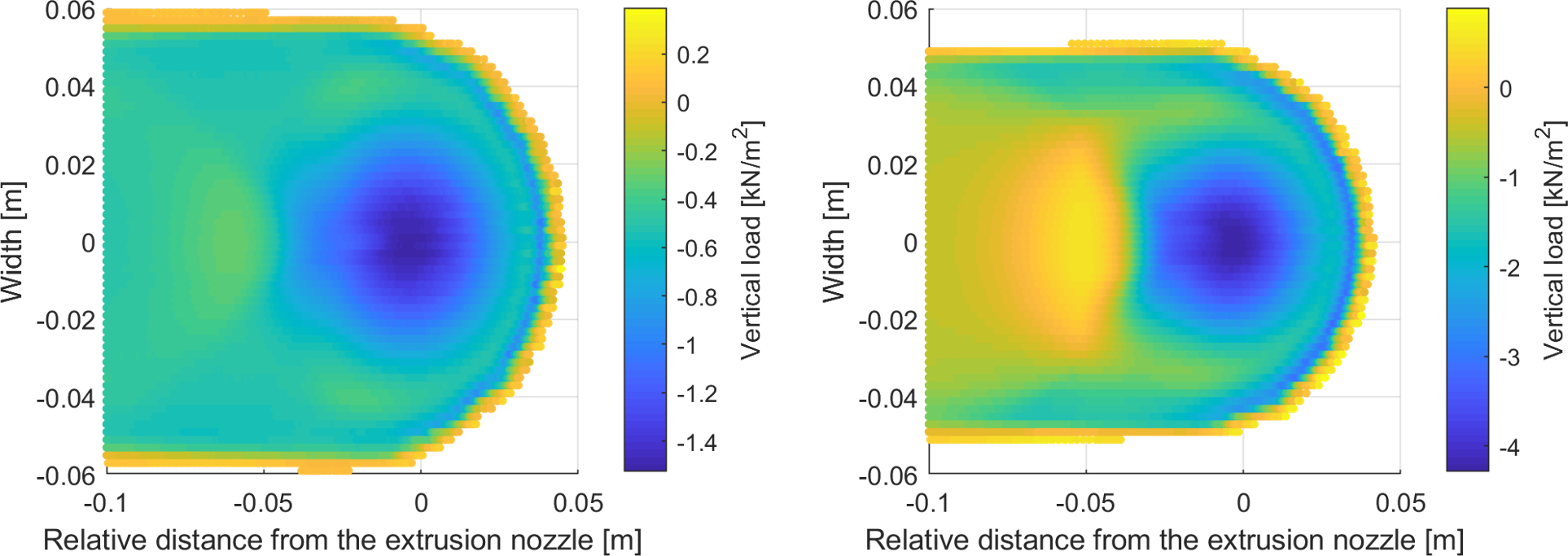

It can be observed that the vertical loads from the inlet flow on lower layers are very sensitive to the material parameters (or the age or state of structuration) of the extruded material. In Fig. 2 the results of the time averaged vertical reaction forces under the extrusion nozzle are given for two materials with different dynamic yield stresses. For both materials the peak value of the vertical load is reached directly under the extrusion nozzle.

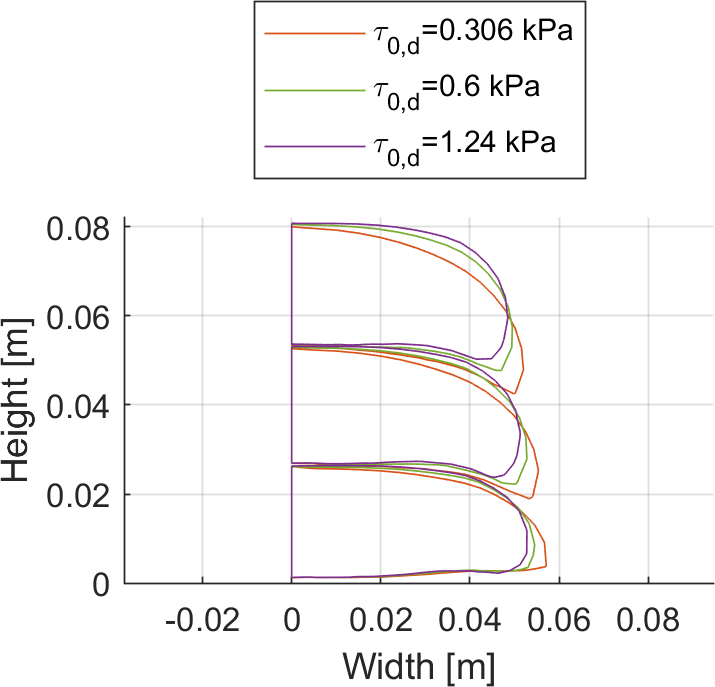

The actual shape and cross-section of the printed layers are given in Fig. 3 for different materials. As can be seen, better shape stability properties are gained for materials with larger dynamic yield stresses. Nevertheless, even though the shape varies for different material parameters, the final height of the printed filaments is the same, when lower layers have a static yield stress large enough to carry all relevant loads.

M.Sc. Janis Reinold

janis.reinold@rub.de

+49 234 / 32-29068

Rodolfo Javier Williams Moises presented his doctoral theses with the title "Computational Modeling

more...

The open access article "Efficient snap-to-contact computations for van der Waals interacting fibers

more...